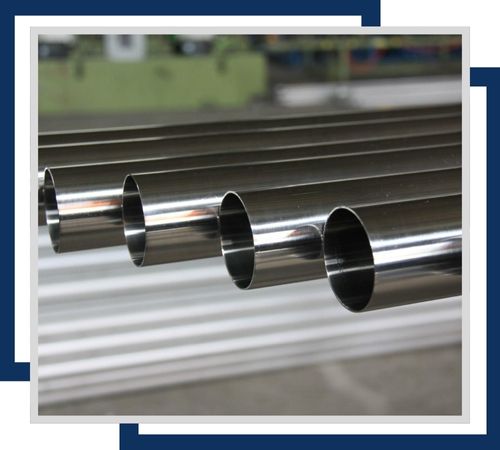

Harshita Stainless is a reliable manufacturer and supplier of Stainless Steel 904L Pipes in Delhi, India. These high-alloy austenitic pipes are intended for aggressive environments and possess superior resistance against sulfuric, phosphoric, and acetic acids. Both seamless and welded types of pipes are offered, manufactured in accordance with ASTM B677 and ASTM B673 standards. Being highly weldable, tough, and having a longer service life, SS 904L pipes are being extensively used in marine, chemical, and pharmaceutical industries. Harshita Stainless provides accuracy manufacturing, rigorous quality assurance, and prompt delivery nationwide in India for various industrial uses.

Stainless Steel 904L contains 19–23% chromium, 23–28% nickel, 4–5% molybdenum, and 1–2% copper that boosts corrosion resistance, particularly against reducing acids. It has a tensile strength of ~490 MPa, a yield strength of 220 MPa, and elongation of 35%. The reduced carbon content enhances weldability without causing intergranular corrosion. These pipes withstand high-pressure and high-temperature operations with reliability, for which they are best suited.

| Standard | ASTM A312 |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1510 °C (2750 °F) | Psi – 75,000 , MPa – 485 | Psi – 40,000 , MPa – 275 | 20 % |

Contact us to get a quick quote for your requirement.

We assures the highest quality standards in its Stainless Steel 904L pipes by higher grade testing procedures. Every pipe goes through extensive mechanical and chemical analysis, such as tensile, hardness, and corrosion resistance tests. All products are supplied along with relevant certificates like Mill Test Certificates (MTC) to assure the supplies are in accordance with international norms.

The SS 904L seamless pipe is a high-alloy austenitic stainless steel known for its exceptional corrosion resistance, making it ideal for harsh environments in chemical and marine industries.

The SS 904L welded pipe offers excellent corrosion resistance and strength, suitable for chemical processing, oil and gas, and marine applications, ensuring durability and reliability in harsh environments.

The SS 904L ERW pipe combines excellent corrosion resistance and high strength, making it ideal for chemical, petrochemical, and marine applications, offering durability and reliability in demanding environments.

The SS 904L EFW pipe provides superior corrosion resistance and high strength, ideal for chemical and petrochemical industries, ensuring durability and reliability in extreme environments and high-pressure applications.

The SS 904L rectangular pipe offers excellent corrosion resistance and high strength, ideal for structural and architectural applications in chemical, marine, and industrial environments, ensuring durability and longevity.

The SS 904L square pipe features high corrosion resistance and strength, making it suitable for structural, architectural, and industrial applications, particularly in harsh chemical and marine environments.

SS 904L Pipes are used widely in chemical processing, oil & gas, marine, and pharmaceutical industries. Their remarkable resistance to acid attacks and chloride-induced stress corrosion cracking makes them suitable for heat exchangers, bleach plants, acetic acid reactors, and seawater handling systems. The pipes are also widely found in desalination plants, power generation, and pulp & paper industries. Because of their superior performance in harsh environments, Harshita Stainless exports SS 904L pipes to clients in Delhi and India looking for long-lasting and corrosion-resistant piping systems.

©2024 Harshita Stainless All Rights Reserved.