Home > Electrodes > AWS Class E312-16 Electrodes

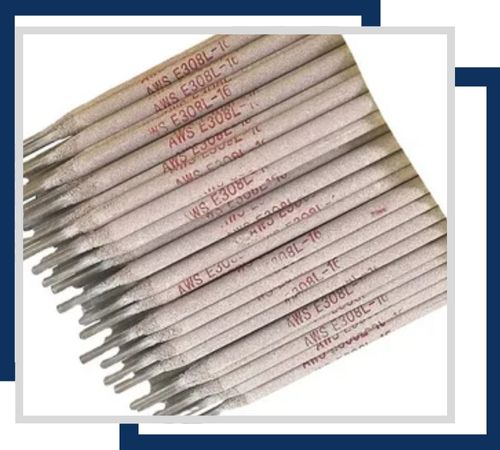

Harshita Stainless, a reputable manufacturer and supplier based in Delhi, India, provides an extensive selection of welding solutions, including top-notch AWS Class E312-16 Electrodes. These electrodes are specifically crafted for welding dissimilar metals and high-strength, challenging steels. Renowned for their exceptional crack resistance and impressive tensile strength, E312-16 electrodes deliver durable and dependable welds even in tough conditions. Harshita Stainless guarantees that each electrode adheres to strict quality standards, ensuring remarkable arc stability, easy slag removal, and minimal spatter. With a solid presence in various industrial sectors, Harshita Stainless has become a go-to supplier for high-performance welding consumables both in India and internationally.

AWS Class E312-16 Electrodes boast a chemical makeup that includes Chromium (28–32%), Nickel (8–10.5%), and low Carbon content (≤0.15%). This distinctive composition provides outstanding resistance to cracking and oxidation. The weld metal produced typically shows a tensile strength of around 860 MPa, a yield strength of about 580 MPa, and an elongation of roughly 25%. These electrodes create robust, wear-resistant welds and can handle moderate dilution from base metals. Their austenitic-ferritic microstructure ensures superior toughness and resilience, making them perfect for welding dissimilar steels and for repair welding of challenging components.

| Classification | AWS A5.4, E312-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E312-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

|

0.15 |

28.0-32.0 | 8.0-10.5 | 0.75 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

Designed for high corrosion resistance, these electrodes feature a light coating for better arc stability and smooth weld appearance. They come in sizes such as 1/8 inch and 3/32 inch, ideal for welding dissimilar metals.

Known for enhanced corrosion resistance, these electrodes have a heavier coating that improves arc stability and slag removal. Available in sizes like 3/16 inch and 5/32 inch, they are suitable for high-strength applications and vertical positions.

These electrodes are designed for shielded arc welding, offering excellent corrosion resistance and superior weld strength and durability. Typically available in 1/8 inch and 5/32 inch sizes, they are used for welding stainless steel to carbon steel.

Harshita Stainless guarantee top-quality AWS Class E312-16 Electrodes through comprehensive testing, including hardness testing, spectro analysis, PMI, flaring, micro and macro tests, pitting resistance and IGC tests. We provide complete documentation, including commercial invoices, packaging lists with net and gross weights, box numbers and labels. Our legalized Certificate of Origin and Third-Party Inspection Certificates guarantee the superior quality and reliability of every product, ensuring unmatched customer satisfaction.

AWS Class E312-16 electrodes are designed for welding dissimilar metals, particularly for joining stainless steels to mild steel or carbon steel. They provide excellent resistance to cracking and high strength, making them ideal for applications in industries such as construction, shipbuilding and heavy equipment manufacturing. The electrodes are used for repairs, maintenance, and fabricating structures exposed to extreme stress or temperature variations. Their versatility and strong performance in corrosive environments make them suitable for diverse welding projects.

©2024 Harshita Stainless All Rights Reserved.