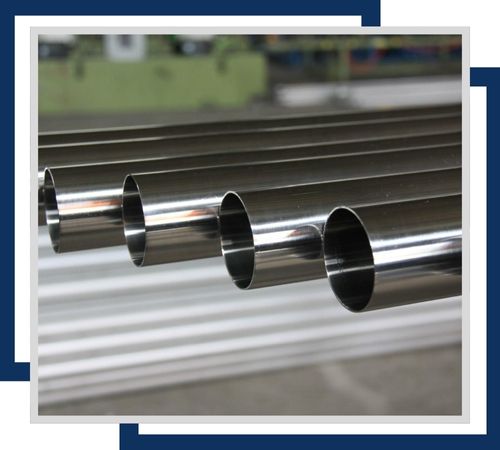

Harshita Stainless is a well-respected manufacturer and supplier based in Delhi, India, specializing in top-notch Stainless Steel 317L Pipes that are renowned for their outstanding corrosion resistance and durability. We take pride in crafting our 317L Pipes from high-quality raw materials and utilizing cutting-edge technology to adhere to strict industrial standards. These pipes are engineered to perform in highly corrosive and high-temperature settings, offering remarkable strength and longevity. With a solid reputation among clients in the chemical, pharmaceutical, and marine sectors, Harshita Stainless delivers precision-engineered pipes that ensure reliable performance and maintain integrity even in the toughest conditions, making us a go-to supplier in the Indian stainless steel market.

Stainless Steel 317L Pipes are composed of significant amounts of chromium (18-20%), nickel (11-15%), and molybdenum (3-4%), which greatly enhance their resistance to corrosion, particularly against chlorides and acids. The low carbon content (maximum 0.03%) minimizes carbide precipitation during welding, helping to prevent intergranular corrosion. On the mechanical side, these pipes boast a tensile strength of around 75 ksi and a good elongation of about 30%, along with excellent toughness and ductility. Their superior resistance to pitting, crevice corrosion, and stress corrosion cracking makes 317L pipes an excellent choice for harsh chemical environments and high temperatures reaching up to 870°C.

|

Dimensions |

: |

ASTM, ASME and API |

|

Standard |

: |

ASTM A312 / ASME SA312 |

|

Size |

: |

1/8″NB TO 30″NB IN |

|

Specialized in |

: |

Large Diameter Size |

|

Schedule |

: |

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Form |

: |

Round, Square, Rectangular, Hydraulic Etc |

|

Type |

: |

Seamless / ERW / Welded / Fabricated / LSAW Pipes |

|

Length |

: |

Single Random, Double Random & Cut Length. |

|

End |

: |

Plain End, Beveled End, Threaded |

| Grade | 310H | |

|---|---|---|

| min | max | |

| C | – | 0.08 |

| Mn | – | 2.0 |

| Si | – | 0.75 |

| P | – | 0.045 |

| S | – | 0.03 |

| Cr | 16.0 | 18.0 |

| Mo | 2.0 | 3.0 |

| Ni | 10.0 | 14.0 |

| N | – | 0.10 |

| Grade | 310H | |

|---|---|---|

| Tensile Strength (MPa) min | 515 | |

| Yield Strength 0.2% Proof (MPa) min | 205 | |

| Elongation (% in 50mm) min | 40 | |

| Hardness | Rockwell B (HR B) max | 95 |

| Rockwell B (HR B) max | 217 | |

Contact us to get a quick quote for your requirement.

We offers complete testing and certification of stainless steel 317L pipe. Our pipes undergo rigorous quality control procedures, including chemical analysis, mechanical testing and theoretical testing. We provide comprehensive certifications of compliance, ensure industry standards are met, and provide exceptional performance, durability and corrosion resistance.

Stainless Steel 317L square pipes are high-corrosion-resistant, low-carbon stainless steel pipes, ideal for applications in marine, chemical, and heat-exchange systems, offering strength and durability in harsh environments.

SS 317L seamless pipes are corrosion-resistant, low-carbon stainless steel pipes known for their high strength and durability, making them ideal for use in harsh environments and chemical processing.

Stainless Steel 317L ERW pipes are electric resistance welded, offering excellent corrosion resistance and strength. Ideal for marine and chemical applications, they provide durability and reliability in challenging environments.

SS 317L LSAW pipes are longitudinally submerged arc welded, offering high resistance to corrosion and stress. Suitable for demanding environments like chemical processing and marine applications, they provide durability and strength.

Stainless Steel 317L round pipes are durable, corrosion-resistant pipes ideal for high-stress environments. They offer excellent resistance to chemicals and harsh conditions, making them suitable for marine and industrial applications.

Stainless Steel 317L welded pipes are manufactured using welding techniques, providing high corrosion resistance and strength. They are ideal for chemical processing, marine environments, and other demanding applications.

Stainless Steel 317L Pipes find extensive use in industries that demand exceptional corrosion resistance and high strength. They are perfect for applications in chemical processing, pharmaceutical manufacturing, marine environments, and power generation facilities. These pipes excel in settings with aggressive chemicals like sulfuric and phosphoric acids. Their ability to resist chloride-induced corrosion also makes them ideal for seawater applications. Furthermore, 317L pipes are utilized in food processing, petrochemical industries, and desalination plants, showcasing their versatility and reliability across various demanding applications.

©2024 Harshita Stainless All Rights Reserved.