Based in Delhi, India, Harshita Stainless is a top producer and supplier of stainless steel 17-4 PH coils. The company, which is well-known for its quality-driven approach, offers high-performance stainless steel solutions designed for demanding industrial applications. The 17-4 PH grade is perfect for the chemical, power generation, marine, and aerospace industries because of its exceptional strength, hardness, and resistance to corrosion. Harshita Stainless uses sophisticated processing methods and stringent quality checks to guarantee accuracy in every coil. With reliable service, competitive pricing, and timely delivery, the company is a trusted partner for stainless steel coil requirements across India and abroad.

Iron, chromium (15–17.5%), nickel (3–5%), copper (3–5%), and trace elements like manganese, silicon, niobium, and carbon make up Stainless Steel 17-4 PH Coils. The exceptional mechanical qualities of this precipitation-hardened grade include tensile strength of up to 1100 MPa, yield strength of approximately 1000 MPa, and hardness of up to 44 HRC following heat treatment. The coils continue to be strong at high temperatures and exhibit outstanding resistance to corrosion in a range of conditions. For critical engineering applications, stainless steel 17-4 PH coils are extremely dependable due to their easy machinability and low distortion during heat treatment.

| Product Name | 17-4 ph stainless steel coil |

| Grades | 301/EN 1.4310/SUS301 |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard as customer’s requirements |

| Thickness | 0.02mm-6.0mm |

| Width | 1.0mm-1500mm |

| Edge | Slit/Mill |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror,etc |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 5-7 working days |

| MOQ | 200Kgs |

| Sample | The sample of 301 stainless steel coil is available |

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 17-4 ph Coils | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.00-18.00 | 6.00-8.00 | – |

| Grade | EN Grade | Yield Strength Rp0.2(N/mm²) | Tensile Strength Rm(N/mm²) | Hardness | Vickers Hardness(HV) | Elongation A50% |

| 17-4 ph Coils | 1.4310 | ≥205 | ≥520 | Annealed | ≥160 | ≥40 |

Contact us to get a quick quote for your requirement.

Stainless Steel 17-4 PH Coil is a high-strength, precipitation-hardening steel alloy known for its excellent mechanical properties and corrosion resistance, which is used in aerospace, automotive, and industrial applications.

Stainless Steel 17-4 PH Welding Coils are high-strength corrosion-resistant coils. They provide good mechanical properties and stability, suitable for aerospace, automotive, and industrial applications.

Stainless Steel 17-4 PH Bright Annealed Coils have a reflective bright surface from the bright annealing process. They have high strength and resistance to corrosion, high strength, and are recommended for applications requiring precision components.

Stainless Steel 17-4 PH Coiled Plated possesses enhanced corrosion strength and toughness properties. These offer higher strength levels in combination with the excellent mechanical properties, suitable for demanding applications including aerospace, automobile, and industries.

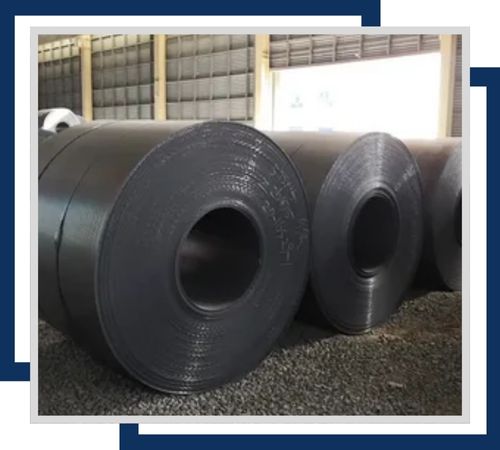

Stainless Steel 17-4 PH hot rolled coils are produced through hot rolling and showcase a high strength and durability. The coils are best suited for applications requiring toughness and resistance to stress and corrosion.

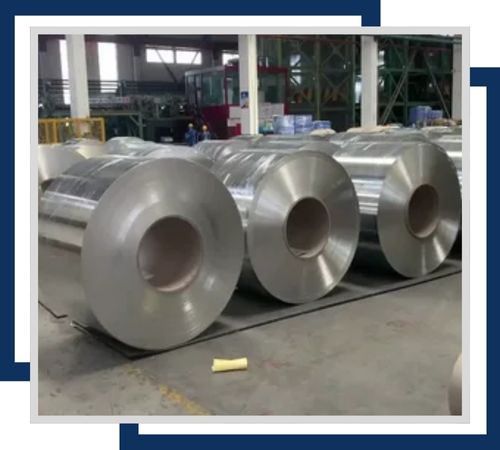

SS 17-4 PH Cold Rolled Coils are cold-rolled coils for a smooth, precise finish with enhanced mechanical properties. Their high strength, excellent dimensional accuracy, and corrosion resistance make them suitable for high-performance applications.

We ensure transparency with our Stainless Steel 17-4 PH Coils as we have the assurance of quality. All shipments are accompanied by necessary documents: a commercial invoice, packing list, fumigation certificate, heat treatment chart, and NABL-approved lab test report. We provide EN 10204/3.1b material test certificate, PMI test certificate, 100% radiography test report, and Third-Party Inspection Certificate. The documentation is thorough and well-structured to ensure total client satisfaction.

17-4 PH stainless steel Industries that require exceptional strength, resistance to corrosion, and dimensional stability frequently use coils. They are utilised for fasteners, structural elements, and turbine blades in the aerospace sector. Because these coils are resistant to seawater conditions, the marine industry uses them in shafts and propeller components. They are used in process equipment, heat exchangers, and reactors in the chemical and petrochemical industries. Other applications include nuclear waste processing, paper mills, and food processing machinery. They are perfect for high-load, high-precision manufacturing settings because of their exceptional mechanical properties and high performance under stress.

©2024 Harshita Stainless All Rights Reserved.