Home > Sheet and Plates > Stainless Steel 440C Sheet and Plates

Stainless Steel 440C Sheets and Plates are high-carbon martensitic stainless steel products that stand out for their remarkable hardness, wear resistance, and strength. These sheets and plates are crafted for situations where top-notch mechanical performance is a must, paired with moderate corrosion resistance. When heat-treated, 440C becomes the hardest of all stainless steels, making it a go-to choice for creating components that face heavy wear, impact, or friction. With their precise flatness and dimensional tolerances, Stainless Steel 440C sheets and plates find their way into tooling, industrial machinery, and specialized engineering settings.

The typical chemical makeup of Stainless Steel 440C features 16–18% chromium and 0.95–1.20% carbon, along with trace amounts of manganese, molybdenum, and silicon. This blend allows the alloy to be heat-treated to reach a Rockwell hardness of up to 60 HRC. On the mechanical side, 440C boasts a tensile strength exceeding 760 MPa and outstanding wear and abrasion resistance, making it perfect for heavy-duty tasks. While its corrosion resistance isn’t as high as that of austenitic stainless steels, it holds up well in mild chemical and moist environments, provided the surface is properly finished and maintained.

| ASME/ASTM Grade | ASTM A480 / ASME SA480 |

| Width Available | 1800mm, 3000mm, 1500mm, 2000mm, 1000mm, 2500mm, 1219mm, 3500mm etc |

| Thickness | 4mm – 100mm |

| Supply Length | 2000mm, 2440mm, 6000mm, 5800mm,3000mm etc |

| Most Commom Finish | SATIN (Met with Plastic Coated), 2B, Cold rolled sheet (CR), BA NO(8), Hot rolled plate (HR), 2D |

| Surface types | sand blast, etching, NO.1, embossed, hair line, 2B, Brush, BA, 2D, checkered, NO.8, 8K, NO.4, mirror, etc |

| Available Plate Form with us | Foils, Perforated Sheets, Plain Sheet, Coils, Rolls, Flats, Shim Sheets, Chequered Plate, Strip, Blank (Circle), Ring (Flange) etc. |

| Mo | S | C | Cr | Si | Mn | N | Ni | P |

| 0.75 | 0.03 | 0..95-1.20 | 16.00-18.00 | 1 | 1 | – | – | 0.04 |

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Rockwell (HR C) | Impact Charpy V (J) |

| Annealed* | 758 | 448 | 14 | 269HB max# | – |

| 204 | 2030 | 1900 | 4 | 59 | 9 |

| 260 | 1960 | 1830 | 4 | 57 | 9 |

| 316 | 1860 | 1740 | 4 | 56 | 9 |

| 371 | 1790 | 1660 | 4 | 56 | 9 |

Contact us to get a quick quote for your requirement.

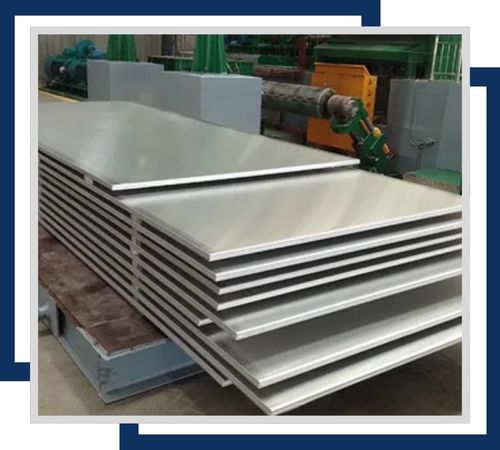

Stainless Steel 440C Hot Rolled Sheets have a high corrosion resistance and durability to be used for applications that need high strength. Usually available from 3mm to 50mm in thickness and up to 2000mm in width. These sheets are used for heavy-duty conditions where strength and toughness are in demand.

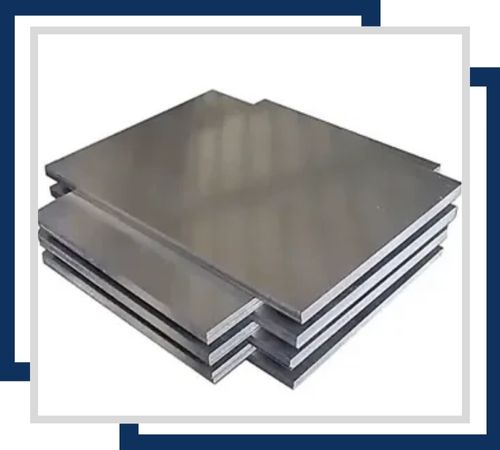

Stainless Steel 440C Cold Rolled Plates have excellent corrosion resistance and a smooth finish. The plates are generally supplied in the thickness of 0.5mm to 6mm and width up to 1250mm. The plates are best suited for applications where precision is needed along with high-quality surface finish.

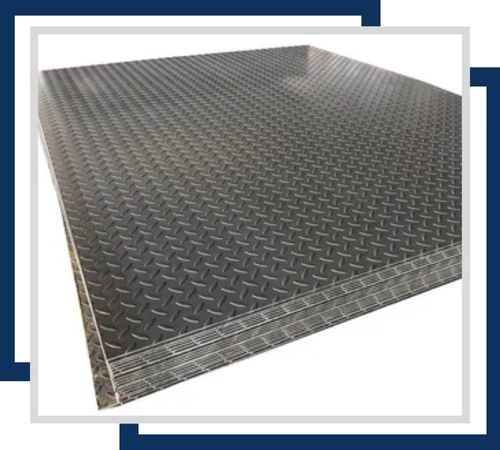

Stainless Steel 440C chequered sheet is used that provides raised patterns for enhanced friction resistance and scratch resistance. Highly corrosion resistant products with sizes as follows: -Thickness range 1.5 mm to 6 mm. They are available in standard sizes up to 1000mmx2000mm. Flooring application, safety purpose, industrial areas, etc.

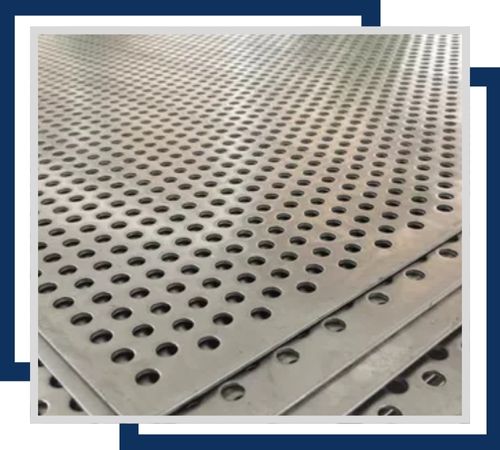

Stainless Steel 440C Perforated Sheets combine corrosion resistance with functional perforations for ventilation and filtration. Thickness ranges from 0.8mm to 6mm, with hole sizes and patterns. The sheets are used in architectural, industrial, and filtration applications where strength and design flexibility are needed.

Stainless Steel 440C shim plates are provided with precise thickness tolerances and excellent corrosion resistance. They are available in the range starting from the thickness of 0.1mm up to 300mm width. It is ideal for applications requiring the proper spacing and adjustment, and for such machinery and assembly, it is preferred.

Stainless Steel 440C Polished Sheets offer a bright luster appearance with excellent corrosion resistance. Generally available in 0.5mm to 10mm thicknesses and up to 2000mm widths. These sheets are used in decorative and high-end applications where aesthetics and durability are important.

Harshita Stainless specializes in bringing excellent customer experience with complete documentation for the superior-quality Stainless Steel 440C Sheets and Plates we offer to our customers. We provide commercial invoices, packing lists, fumigation certificates, heat treatment charts, quality assurance plans, and NABL-approved lab test reports that prove authentic and superior quality. In addition, all our Stainless Steel 440C Sheets and Plates are provided with various test certificates such as MTC according to EN 10204/3.1b, PMI Test Certificates, 100% radiography test reports, and Third Party Inspection Certificates. These detail documents reflect that we are very customer-centric, and we aim for excellence with our products.

Stainless Steel 440C Sheets and Plates are commonly used in making surgical instruments, bearings, valve components, knives, molds, and dies. They shine in applications that demand a mix of high hardness, edge retention, and dimensional stability. Industries like aerospace, defense, automotive, and precision tooling often rely on 440C for its ability to withstand mechanical stress. Although it may not be the best fit for highly corrosive environments, it excels in clean or controlled conditions where durability and wear resistance are paramount.

©2024 Harshita Stainless All Rights Reserved.